Services

Your Strategic Partner

Field Verification

Field verification is when a PE (Professional Engineer) travels to a specific facility to inspect a system(s). Read More…

Engineering Peer Review

An EPR is a process through which professional engineers evaluate, maintain, or monitor the quality and utilization of engineering services, Read More…

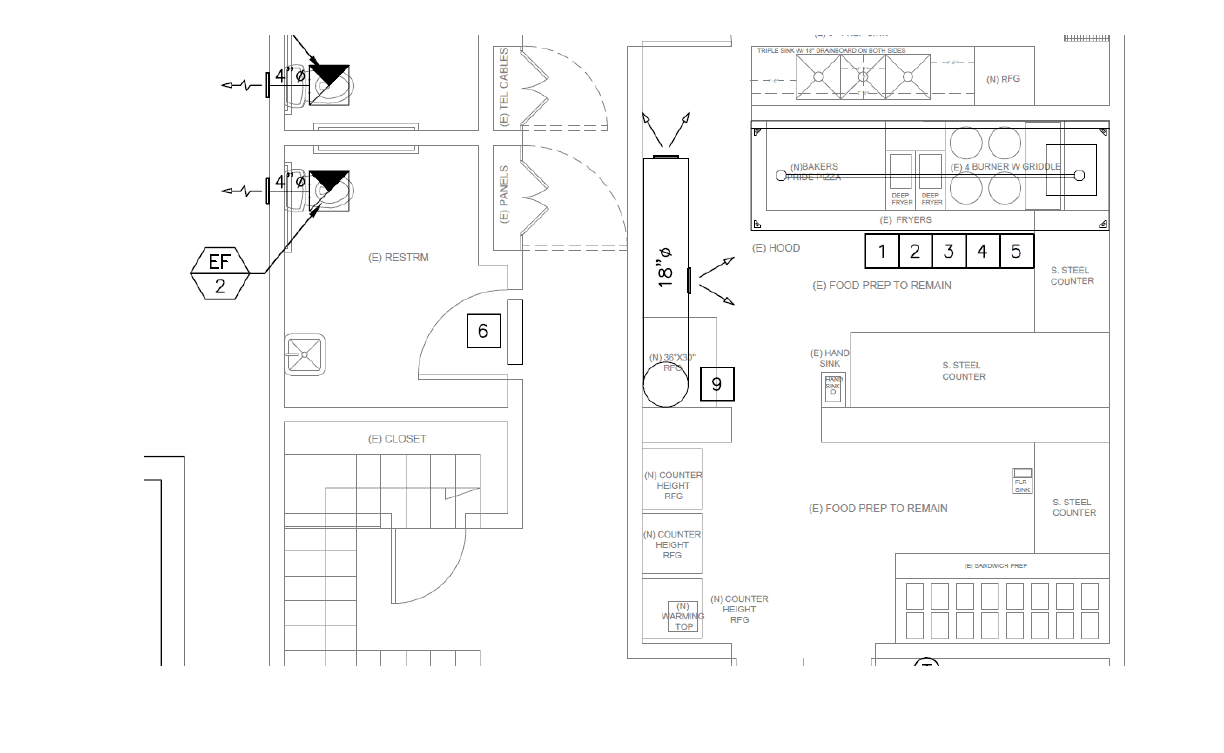

MEP Engineering and Architects: (Price Determined by Facility Size and Location)

We will help you with the complete building plans and approvals from the local jurisdiction for your facility. Read More…

Facility Layout

Our licensed engineers can help you with the initial step of your facility layout and equipment selection. Read More…

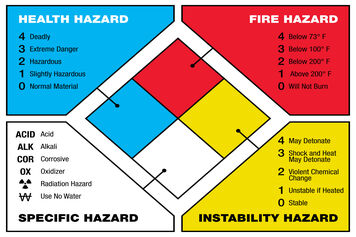

Fire Protection Engineering (Hazard Report)

A facility Hazard Analysis Report can be provided by an FPE if requested by AHJ. We have partnered with Read More…

Process Hazard and Airflow Analysis

A Process Hazard and Airflow Analysis Report can be provided by our experts if requested by AHJ. Read More…

Energy Efficiency/Title 24 Calculations

Our engineers specialize in title 24 or energy efficiency calculations and can help provide the Read More…

GMP Compliance

Our Engineers have extensive experience in assisting clients towards GMP compliance. We help with equipment Read More…